Power Testing (PWT)

A new power test solution (hardware and software) is currently under development and scheduled for release in 2021. The PWT software is still available for customers having a DA hardware unit for single or dual channel tests. Please contact support(at)klippel(dot)de for details.

Features and Benefits

- Long term driver testing without sensor

- High-speed temperature monitoring

- Ideal for thermal parameter measurement

- Full mechanical identification of transducers (woofer, micro-speaker)

- Mechanical and thermal load versus time

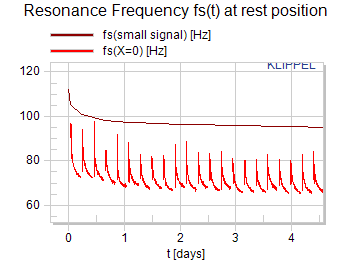

- Permanent identification of voice coil offset and fs (no persistent excitation by stimulus required)

- Monitors destruction process

- User defined failure limits

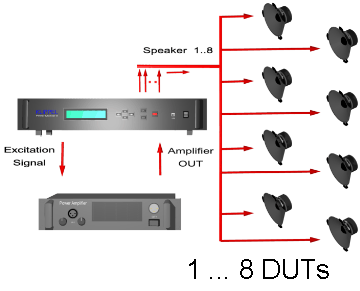

- Measures up to 8 DUTs simultaneously

- Stand-alone operation

- Driver status displayed on hardware

- Analysis of recorded measurement

- Internal signal generator

- Stimulus shaping/filtering

- Variable slope (6,12, and 24 dB in high-pass and low pass filter)

- Any external signal (music)

- Control of amplitude at terminals

- Stepping amplitude

- Cycle scheme (ON/OFF)

The Power Test Module (PWT) and the hardware platform Power Monitor 8 (8 channels) allow performing destructive tests of transducers with permanent monitoring of electrical, mechanical and thermal state variables and parameter variations. An externally or internally generated excitation stimulus may be controlled in amplitude, spectral bandwidth or crest factor and may be supplied to the transducer permanently. The increase of the voice coil temperature can be measured by monitoring the electrical impedance of the speaker using a conventional AC-coupled amplifier (The mechanical parameters and the instantaneous displacement of a transducer can be monitored by impedance measurements dispensing with acoustical, mechanical or thermal sensors). The speaker parameters and state variables are sampled periodically and stored in a buffer in the hardware unit. Connecting a computer via USB to the hardware platform allows for viewing and investigating the destruction process in detail. This information is crucial for finding the physical cause of the failure and for understanding the temporal order of the destructive events. This enables the user to assess the maximal limits of the transducer more precisely.

Specification

Products

PWT Lite

Was designed for traditional power testing, monitoring voltage, current, resistance and temperature.

PWT Pro

Also provides the "Transducer Identification" mode, which monitors the large signal parameters during the power test and helps find the cause of defects (woofer, micro-speaker, vented box).

PWT Intermittent Summary Tool

Provides a comprehensive summary of power test measurements, interrupted by cooling pauses and small signal measurements.

Standard Measurements performed by PWT

Requirements

PWT Intermittent Summary Tool

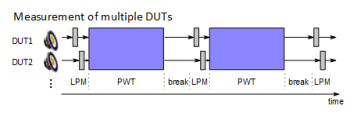

The PWT Intermittent Summery Tool provides a comprehensive summary of intermittent testing. Long-term monitoring tests are used to observe the loudspeaker parameter variation over a long measurement time (from hours to month) while using a natural audio stimulus (e.g. music) or an artificial test signal (e.g. noise). For monitoring of large signal parameters, this is done by on-line testing in the large signal domain using the normal power test stimulus. Monitoring of the small signal parameters requires intermittent testing by interrupting the power test and performing separate small signal measurements. A pause is included in the measurement to assure any transient effects from the large signal measurements have decayed (e.g. temperature).

Templates coming with the PWT module:

PWT 8 Woofers Param. ID Noise | Parameter Identification of Woofers using internal test signal (no cycling, no stepping) |

PWT EIA accelerated life test | Accelerated life testing according EIA 426 B A. 4 using any external signal to monitor temperature, power and resistance |

PWT IEC Long term Voltage | Power test to determine long-term maximal voltage according IEC 60268-5 paragraph 17.3 without parameter measurement for one device monitoring voltage, resistance, temperature and power |

PWT IEC Short term Voltage | Power test to determine short term maximal voltage according IEC 60268-5 paragraph 17.2 without parameter measurement applied to 1 DUT monitoring temperature, power and resistance |

PWT Powtest (fast Temp.) | Power test for fast monitoring of temperature, power and resistance without parameter measurement using external continuous signal (noise) supplied to IN1 |

PWT Powtest EXT. GENER. | Power test for monitoring temperature, power and resistance using external continuous signal (noise) supplied to IN1 |

PWT Powtest LIMITS | Power test to find maximal input voltage, power and temperature limits without parameter measurement applied to 1 DUT |

PWT Powtest MUSIC | Power test without parameter measurement monitoring temperature, power, voltage and resistance using any external signal |

PWT Powtest SWEEP | Power test for measuring the thermal time constant of the voice coil using sweep signal with low crest factor |

PWT Powtest TIME Const. | Power test for measuring time constant of voice coil using internal test signal with cycling (ON/OFF phase) |

PWT Woofer Param. ID MUSIC | Parameter Identification of Woofers |

PWT Woofer Param. ID NOISE | Parameter Identification of Woofers |

Related Information

Standards

Consumer Electronics Association

CEA-CEB19, CEA-2006-A, CEA-2019

International Electrotechnical Commission

IEC 60268-5, IEC 60268-7, IEC 60268-21, IEC 60268-22, IEC 62458, IEC WD 63034

European Standards

BS EN 54-24

Patents

Germany: 10 2007 005 070; USA: US8,078,433B2; China: ZL200810092055.4; Japan: 5364271; India: 162/DEL/2008; Germany: 10 2012 020 271 7; USA: 10,110,995; China: 201380054458.9;Korea:10-2015-7012390;Taiwan: 102137485;India: 844/MUMNP/2015